Liquid Oxygen

Oxygen is one of the gases in the air at room temperature. But can we liquify oxygen?

As oxygen boils at -183°C (90K) and liquid nitrogen boils at -196°C (77K) we can use liquid nitrogen to liquify oxygen. The usual way to do this is to pass oxygen gas from a compressed gas cylinder through a coil of copper hollow copper pipe which is submerged in liquid nitrogen. The copper coil is a good conductor of heat and has a large surface area and so the oxygen liquifies.

This photo shows the apparatus used to liquify oxygen without a compressed gas cylinder. There is a conical flask with Manganese (IV) oxide and Hydrogen Peroxide on the right. Following the orange rubber hose to the left there is then a boiling tube trap to prevent any Hydrogen Peroxide accidentally being taken into the coil. Again following the orange rubber hose to the left there is the copper coil in a liquid nitrogen bath. The outlet from the coil is connected to a second boiling tube trap (where the liquid oxygen collects) which is in a liquid nitrogen bath made using a Pyrex beaker. The rubber hose on the left is connected to a water tap vacuum pump to draw oxygen through the apparatus.

However, liquid oxygen can also be made in small quantities without a compressed gas cylinder. A chemical reaction between Manganese (IV) Oxide (Manganese Dioxide, MnO2) and Hydrogen Peroxide (H2O2) produces oxygen gas. This is passed through a trap and then into the copper coil. The copper coil is submerged in a bath of liquid nitrogen. As the liquid oxygen comes out of the coil it is collected in a second trap which is in a liquid nitrogen bath to prevent the oxygen boiling off. The other side of the trap is connected to a water tap vacuum pump which draws the oxygen through the apparatus.

The copper coil is 6mm diameter copper pipe bent around a suitable cylindrical object (eg a scaffold pole) around 7.5cm in diameter. This is placed into a polystyrene bowl - basically a piece of packaging. The holes in the polystyrene which the coil was inserted though were sealed using 2 part epoxy. Check the epoxy active ingredients list for bisphenol-A epichlorohydrin as this seems to withstand the cold temperatures very well.

These photos show close ups of the copper coil and nitrogen bath. The coil is made of 6 turns of 6mm diameter copper pipe.

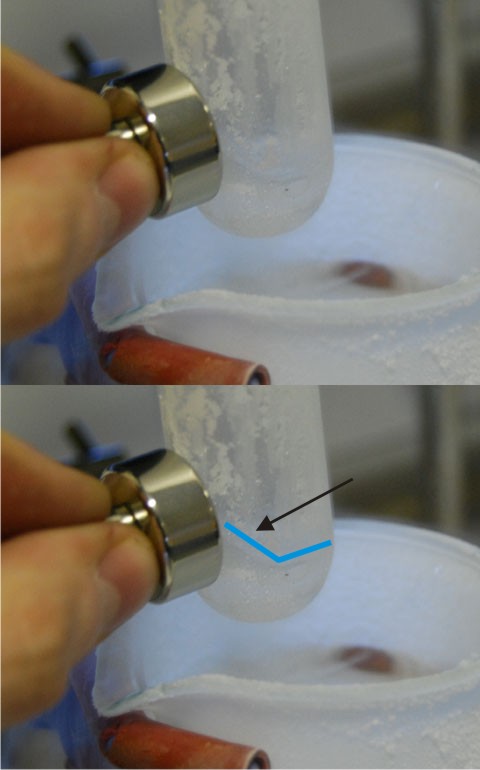

After leaving the apparatus running for around 10-15 minutes a small amount of liquid oxygen was collected in the bottom of the boiling tube. This can be confirmed by the liquid being dragged up the side of the boiling tube by a magnet - liquid oxygen is a paramagnet - i.e. it is attracted to an applied magnetic field. Pure liquid oxygen is a light blue colour - a hint of blue can be seen in the video below, however I suspect that there is some nitrogen contamination as the apparatus is not air tight.

This photo shows liquid oxygen in the bottom of a Pyrex boiling tube. The silver coloured magnet on the left hand side of the photo is drawing the liquid oxygen up the side of the boiling tube as the liquid oxygen is paramagnetic.